AEG Industrial Engineering!

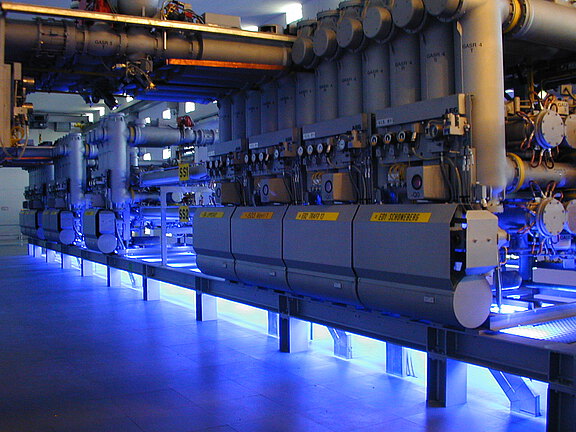

Power generation and power engineering, drive and plant engineering, components and spare parts, maintenance and service, these are the industrial core fields of AEG Industrial Engineering AG. The main focus of our plant engineering is on switchgear and switchgear equipment, drive and automation systems, transformers and generators/turbines and gas engine diesel gensets. General industrial electronics and high and low voltage compensation systems are part of AEG Industrial Engineering (AEG IE AG) as well as the supply of excitation systems (SEE) and starting converters (SFC). AEG IE AG is a company for electrical installations for industry, for the energy sector and for transport. You can find us at the traditional location of AEG Industrieanlagen, at Hohenzollerndamm in Berlin.

Together with our representatives and our local subsidiaries, we serve our international clients. We supply spares and new equipment to our clients. We consult, design and supply for new equipment and revamp existing plants. Many of our engineers are familiar with industrial plants, ship technique and power plants supplied by AEG in the past. We deliver devices and systems make the start up of the equipment and take care until production starts. If customers need consulting services for economizing energy in large drives for pumps and fans, we can help.

Our after sales service, inspections and repairs of AEG components like Kanis turbines, transformers, switchgear or other devices help customers to run and stabilize their production plants. Together with our partners we can deliver complete compact steelworks including scrap sorting and the electric arc furnace EAF and LF. Where required, we can also provide rolling mills for the production of construction steel or profiles.