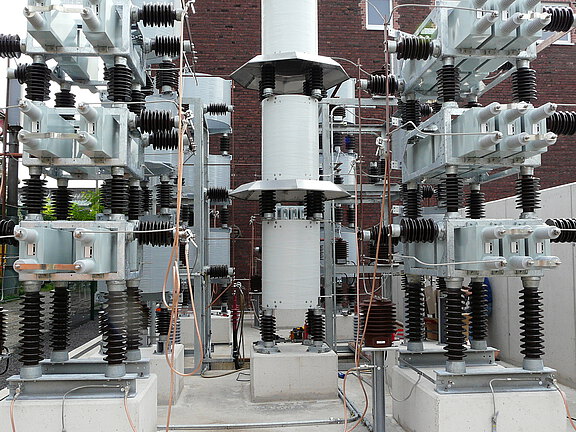

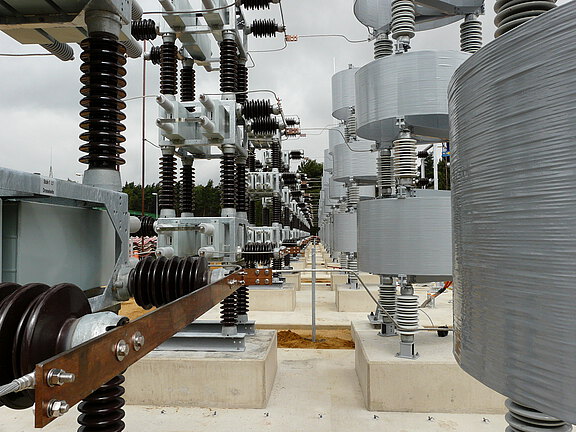

Compensation equipment

We analyse the condition of your grid regarding line perturbances by large loads, serve as consultant for ultimate consumers and supply complete compensation plants. For equipment already in operation, we offer concepts for optimization and furnish modern, digital TCR controls. Our services include planning, design, commissioning and maintenance. For the steel industry we make use of mathematical models for the electric arc furnace (AC or DC) and we are in a position to inform about the disturbances to be expected. With the help of computer-based simulations, the layout of the components of a compensation system can be determined.